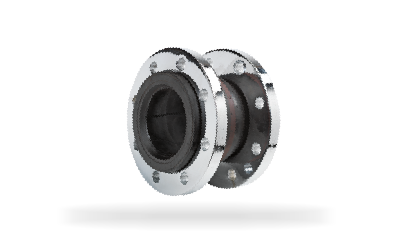

Expansion Joints

Expansion joints are flexible connectors designed to absorb thermal expansion, vibrations, and misalignment in piping and duct systems. Made from materials such as rubber, metal, and fabric, they help prevent structural damage and enhance the longevity of industrial systems. Widely used in industries like HVAC, power plants, oil & gas, and water treatment, expansion joints ensure smooth operation by compensating for movement and reducing stress on pipelines.

Expansion joints are critical components in piping and ductwork systems, designed to absorb movements caused by thermal expansion, mechanical vibrations, and misalignment. By allowing controlled flexibility, they prevent structural damage, reduce stress on connected equipment, and ensure the smooth operation of fluid and gas transfer systems.

These joints are available in different types, including metallic, rubber, and fabric expansion joints, each offering specific benefits for various applications. Metallic expansion joints are ideal for high-temperature and high-pressure environments, while rubber and fabric joints provide excellent flexibility and resistance to corrosion and chemical exposure.

Commonly used in industries such as HVAC, power generation, oil & gas, chemical processing, and water treatment, expansion joints play a crucial role in maintaining system integrity and operational efficiency. With their ability to absorb shocks, compensate for pipe movements, and reduce maintenance costs, expansion joints are indispensable for modern industrial applications

Reviews

There are no reviews yet.